PS Audio

PS Audio USA - 1 Meter Power Cable - Statement Series Audiophile

PS Audio USA - 1 Meter Power Cable - Statement Series Audiophile

Couldn't load pickup availability

PS Audio USA - 1 Meter Power Cable - Statement Series Audiophile

WHY PS AUDIO CABLES?

Molded connectors, not the conventional hospital grade connectors found on most cables

as seen below.

The difference is in the details

To build the world’s best power cables, we started from scratch and worked our way up.

What was the first step? Redesign the connectors themselves.

PS Power SC power cables use our custom made male and female connectors. In contrast, every aftermarket high-end power cord uses an off-the-shelf male and female AC power connector. These off-the-shelf connectors find their way on cables as low as $50 to as high as many thousands of dollars.

Some folks (who don’t yet know better) actually consider these old technology connectors to be state-of-the-art. But, they are not. Here’s why…

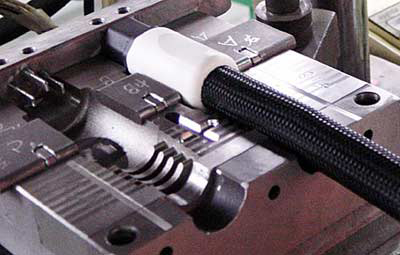

Take a look at the way the plug and IEC connectors are made in this photo of a ‘state-of-the-art’ hospital

grade aftermarket connector used on many high end power cords.

Note the plug prong is a three-piece affair made from a piece of stamped metal (the IEC is constructed in the same manner). The three parts are the prong, the clamp cover and the screw. The prong and clamp are made from brass and the screw is constructed of steel.

To build a high performance power cord with these off-the-shelf connectors, you have to accept a compromised connection scheme: basically you insert the conductor into the clamp and tighten; the steel screw is used to hold the conductor in place.

The problems with this style of build:

Multiple pieces are prone to oxidation, corrosion and poor fit

Using a steel screw to pressure copper against the brass prong is not the best connection in the world

It holds little promise of longevity

Created male and female

To solve the problems of longevity, connectivity and loss of surface area, PS engineering went to work designing an entirely new male and female connector from the ground up.

To address the issue of multiple pieces of stamped and dissimilar metals in the actual prong itself, we machined our prongs out of a solid block of high copper content brass, and then polished both the female and male prongs – and finally nickel plated all surfaces and polished them again.

By machining the new prongs from a solid block of material, we were also able to resolve the dilemma of the unnecessary hole in the mating prong as well as the dissimilar metal problem.

Even the female side of the PS power cable is revolutionary as well. So strong is the gripping force of the PS Power IEC female end that you can literally dangle a piece of equipment from the PS power cable without it falling! Try that with another power cable!

Hot and Cold

Once we had a single piece of machined metal with an appropriately sized hole to receive the cable’s

conductor, it was time to do a better job of attaching the conductor to the connector.

Traditional off-the-shelf stock power cords simply squeeze the brass end over the wire. Most “high-end” power cables use a tightened steel screw to hold the conductor against the prong. Both of these methods are prone to oxidation and corrosion AND loss of connectivity due to repeated twisting of the connector.

The PS Power Punch and SC series each employs two forms of welding to fuse the conductor to the machined prong: cold and hot.

Cold welding exerts thousands of pounds of pressure supplied through the force of a hydraulic press to squeeze the two metals together such that the metal structure of the two pieces actually fuse together.

To further insure a perfect connection, we then solder each of the machined prongs with high silver content solder in a hot welding technique that creates the perfect bond.

Hermetically sealed for protection

To address the issue of long term conductivity and eliminate problems such as oxidation, PS Power engineers designed an outer shell that is molded over the machined, cold and hot welded connectors.

This molding process, which also incorporates a built in strain relief, keeps the outer elements away from the all-important fusion of the prongs to the conductors.

The custom connectors on the PS Power Punch and SC alone will revolutionize the category and set new standards for state-of-the-art status in power delivery systems.

- WOW! Solid silver conductors

- PCOCC single crystal copper7 gauge overall

- Machined prongs

- Removable ground pin

- Ferrite impregnated jacket

- Unrestricted power delivery

- Finest power cable in the world

- One single crystal barrier

- Huge surface area for connections

- Cleans while it powers

- No comprimse power delivery

- Lower noise floor

- Ability to eliminate ground loops

It’s what’s inside that counts

How do we create a new power cable that outperforms the xStream Statement SC? Well, to use a restaurant analogy, if you’re already serving gourmet food cooked by the world’s best chefs, then all that is left for improvement are the ingredients themselves.

The Premier power cable was sweated and worked over for a long, long time by PS Engineering. Concocted from a blend of the world’s finest conductors: – PCOCC single crystal copper and solid 99.9% pure silver solid core – it’s surrounded by multiple shields and encased in a luxurious cloth outer jacket. To top it all off, it’s then connected with our hand machined male and female connectors, resulting in the Premier SC – the new standard by which all others will be judged.

To build the Premier, we started with a solid silver, solid core 14 gauge power cable. This is the same gauge

power cable as most equipment comes with as standard.

We listened to the performance of this solid silver cable and while the top end and soundstaging were breathtaking, the midbass, body and bass response of the power cable were lacking.

To build up these areas of the sonic tapestry, we began to add pure, single crystal PCOCC copper in varying strand widths, from fine 36 gauge to heavier solid core until is sounded perfect.

What we wound up with is an overall wire gauge of 7, which is huge! 25% of the Premier is solid silver and the balance is PCOCC single crystal copper.

But performance is the key

We’re convinced that nothing has even come close to the performance levels of great equipment when it is plugged in with the Premier. From power amplifiers, to CD players, preamps and DAC’s, the Premier is the defining connection between the wall socket, Power Plant or power conditioner of any kind.

The Premier brings a new level of refined beauty, power and spacious performance to high-end, high-performance systems. It’s a breathtaking openness, with quick and lightning transients and a warmth and richness we’ve never experienced in any system. Those are just a few of the benefits of powering the system with the Premier.

Conductors are the key in the Premier

Any power cable is only as good as the conductors inside and the level of shielding and connectivity it possesses. The Premier uses the two best conductors in the world, solid pure silver and single crystal PCOCC copper.

Silver is the best conductor on the planet

When Samuel F. B. Morse tapped out, ‘What hath God wrought,’ on May 24, 1844, the contact points on his telegraph were silver. The high amperage required to push the signal over iron wires from Baltimore to Washington, D.C., demanded a high capacity, non-corroding make/break contact; only silver could do the job.

Silver is used in most expensive switch contacts, but because of its extremely high price, it’s rarely used as

a large electrical conductor for AC power. But that’s a shame, because silver has the lowest resistance and the best conducting properties of any material in the world! And it’s nearly perfect for AC power distribution.

In the Premier, we spared no expense to build the world’s best power cable.

Solid silver, while the best conductor, isn’t the only ingredient needed. We’ve found that for best AC power delivery, silver must be combined with pure copper in just the right amounts for the highest level of performance. Actually, it’s a bit like a chef refining his recipe.

That’s where PCOCC comes in.

Almost unobtainium

In 1985, a method for the extrusion of a grain free copper wire was developed by Professor Ohno in Japan. Known as The Ohno Continuous Casting Method, molten copper is forced out of the mold and very slowly draws the grain down the conductor’s length, creating a ‘single grain structure’.

Unfortunately, there’s only one machine in the world that creates single crystal copper. It’s owned by Furukawa metals in Japan. This one machine is so specialized that they can only run it every other day. The casting machine needs an entire day to cool down and be prepared for the next run.

This rare single crystal (SC) copper is nearly ten times more expensive than OFC copper and is the second best conductor in the world (next to silver). Not surprisingly, it is difficult to purchase. And, as you might imagine, there are relatively small quantities made at any one time.

PS Power has secured futures on this material for both the xStream SC Series of power cables as well as the Premier. So we can build our power and audio cables with only the finest of materials, directly cast out of this single machine in Japan.

Putting it together

The importance of the conductors cannot be understated. By combining both solid silver and PCOCC copper in just the right proportions, the Premier is able to lay claim to being the best power cable in the world.

But shielding these pure conductors from the outside world is important as well.

The Premier has multiple shields and each of the shields lowers noise. The individual shields make sure that

noise from within the power cable as well as noise from outside the power cable never see each other. The Premier is one of the quietest power cables in the world.

But shielding can only do so much. In the xStream and Premier cables, the AC gets cleaner as it passes through the power cable. The outer jacket of the Premier acts as a filter to actually clean the AC power as it is delivered to your equipment!

Ferrite, a magnetic material that acts as a noise filter, is impregnated in the Premier’s outer jacket. So the cable cleans as it delivers unrestricted power to your equipment.

Despite the heavy PCOCC and solid silver content, ferrite jacket and multiple shields, the Premier cable is still flexible enough to be used in any situation. So you can see why this is truly a state of the art power cable by anyone’s standards.

Share